Industrial Projects Management

Together with our partners we present comprehensive solutions in various industrial areas: mechanical installations (production lines and transport), electrical installation and automation systems, AutoID (bar code readers, RFID and labeling and software solutions (traceability and communication with ERP systems).

We manage "turnkey" projects together with our customers at every stage of the process, initial organization, planning and implementation, monitoring and final control. |

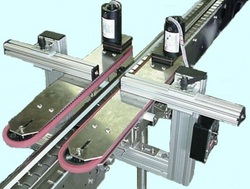

Industrial Automation

Productivity and competitiveness combined with cost reduction are key factors to the development of a company. Production systems automation is nowadays essential to the profitability of a company. The use of programmable controllers (plc), dedicated process controllers, management and data acquisition softwares, are the basis of the control and management of the entire production process in several areas and industrial sectors.

As a solution provider and a systems integrator SISTECnais applies and integrates equipment of the most recognized in industrial automation brands, Siemens, Schneider Electric, Omron, Mitsubishi and Panasonic, among others.

Information on the operation status and production equipment efficiency, worktime and deadtime evaluation, production quantity are all key factors. Field networks like DeviceNet, Modbus, Profibus and others are used for data collection in supervision softwares, allowing production management and appropriate intervention.

Production process monitoring and data collection using SCADA software allows high potential in terms of graphics, alarms, statistics, preparing recipes, etc.. enabling the user to monitor plant operation and performance.

As a solution provider and a systems integrator SISTECnais applies and integrates equipment of the most recognized in industrial automation brands, Siemens, Schneider Electric, Omron, Mitsubishi and Panasonic, among others.

Information on the operation status and production equipment efficiency, worktime and deadtime evaluation, production quantity are all key factors. Field networks like DeviceNet, Modbus, Profibus and others are used for data collection in supervision softwares, allowing production management and appropriate intervention.

Production process monitoring and data collection using SCADA software allows high potential in terms of graphics, alarms, statistics, preparing recipes, etc.. enabling the user to monitor plant operation and performance.

AutoID + RFID Labeling and Tagging

We implement automatic identification systems with barcodes readers and RFID systems. RFID tags can be passive or active allowing the reading and writing of data and its storage for later access. It is a very important tool whenever it is necessary to trace the production process. There are several industries where this technology is being used, the automotive sector is perhaps the most significant one. Other main areas go from hospital applications, tracking and animal identification, tracking and fleet vehicles, safety in the commercial area among others.

We develop and integrate labeling and tagging solutions, using inkjet systems, HP ink jet technology, laser marking systems and automatic labeling systems for boxes and palletes production lines.

We develop and integrate labeling and tagging solutions, using inkjet systems, HP ink jet technology, laser marking systems and automatic labeling systems for boxes and palletes production lines.

Artificial Vision Systems

We develop quality control and inspection solutions based on artificial vision systems, suitable for verification processes in various industrial areas, products validation and raw materials, sectors such as plastics, textiles and footwear, automobile, metallurgy, ceramics, wood , paper, pharmaceutical, food are some of them.

Artificial vision systems applications:

Artificial vision systems applications:

- Measurement - Measurement of diameters, distances, lengths in parts, molds, bolts, screws, etc..

- Positioning - Precise location of products in production lines, use of robots.

- Identification - OCR, reading barcodes and 2D matrix. Use in identification systems, traceability and labeling of products.

- Inspection - Automatic color or positioning inspection, surfaces and finishing defects, filling levels and checking assembly, quality control, packaging and products labeling.

Equipments Prototypes

We design, develop and manufacture prototypes and small equipment machines for customized solutions and adapt existing automated industrial machinery. We design and develop hardware and software solutions tailored for different applications.